09

2021

-

04

Significant improvement in spray quality

2021-04-09 14:04

Author:

Significant improvement in spray quality

With the increase of consumer demand, good quality and beautiful vision determine the degree of recognition and popularity of a product in the market. Therefore, the company adheres to the business philosophy of "quality first, customer first" and adopts advanced spray coatings. The technology of phosphating, electrophoresis, spraying, overprinting, etc., uses strict paint in-plant control, spraying process control, finished product inspection and other means to ensure product quality while pursuing visual perfection, providing consumers with high-quality beauty and peace of mind Reliable product.

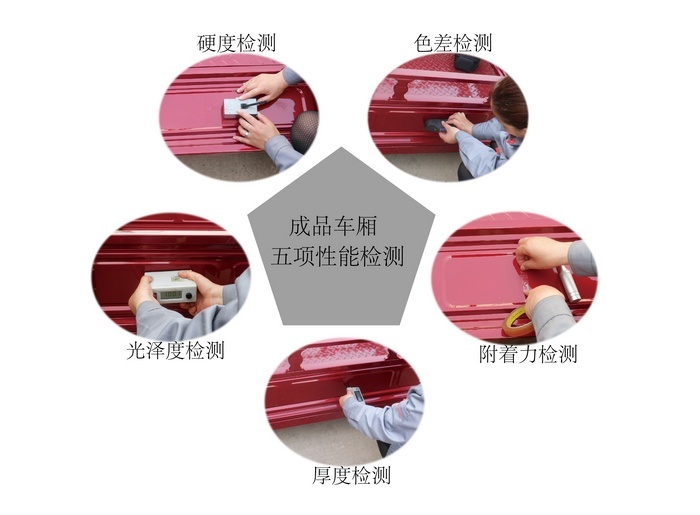

For each paint purchased into the factory, each paint supplier is required to provide a corresponding paint test report, and the content of various components of the paint must be explained. For the test items that the company cannot meet at this stage, we entrust the country The inspection department inspects it, and the special personnel of the quality control section conduct preliminary inspections based on this. After passing the inspection, they will be put into the warehouse for trial. In the trial phase, various technical parameters of the paint will be tracked and measured, such as paint adhesion, hardness, and gloss. , Color difference, etc. (as shown in the performance test of the finished car), and then analyze the test data, and review the paint in strict accordance with the company's quality requirements and industry standards. After all performance indicators have reached the company's quality requirements, the Notice of use under the workshop. Resolutely do not use paint that cannot meet the company's quality requirements.

In order to ensure the quality of spraying, we perform layer-by-layer processing for products that have passed inspections and trials during use, and we have specialized personnel to perform various inspections such as particulate matter, orange peel, sagging, and leaking spray on each finished car. Gloss, thickness, chromatic aberration, adhesion, etc. are continuously spot-checked to find and solve problems in time to ensure that all links of spraying control are under monitoring, so that the quality of product spraying is guaranteed.

Through the tracking and control of paint use, our spraying quality has been significantly improved this month. The gloss of the carriage has been increased to more than 100, and the thickness has also been controlled between 55 and 80. The color difference between the carriage and our color plate Strictly controlled within 4, the adhesion hardness has been greatly improved on the basis of the original qualification. The spraying quality not only satisfied the company's leaders, but also received unanimous praise from dealers. The entire vehicle was put on the market and was also recognized by customers and friends. Our efforts have been recognized by everyone, and everyone's recognition has given us the motivation to make better quality. I believe that the quality of spraying will be better, and the quality of Loncin will be better.

Significant,improvement,in,spray,quality

Previous page

Next page

Previous page

Next page

RELATED BLOG

Steel prices continue to soar! Tricycle industry is facing a tough battle!

First, look at the international environment!

2021-04-09